Understanding Commercial Electrical Maintenance

Definition of Commercial Electrical Maintenance

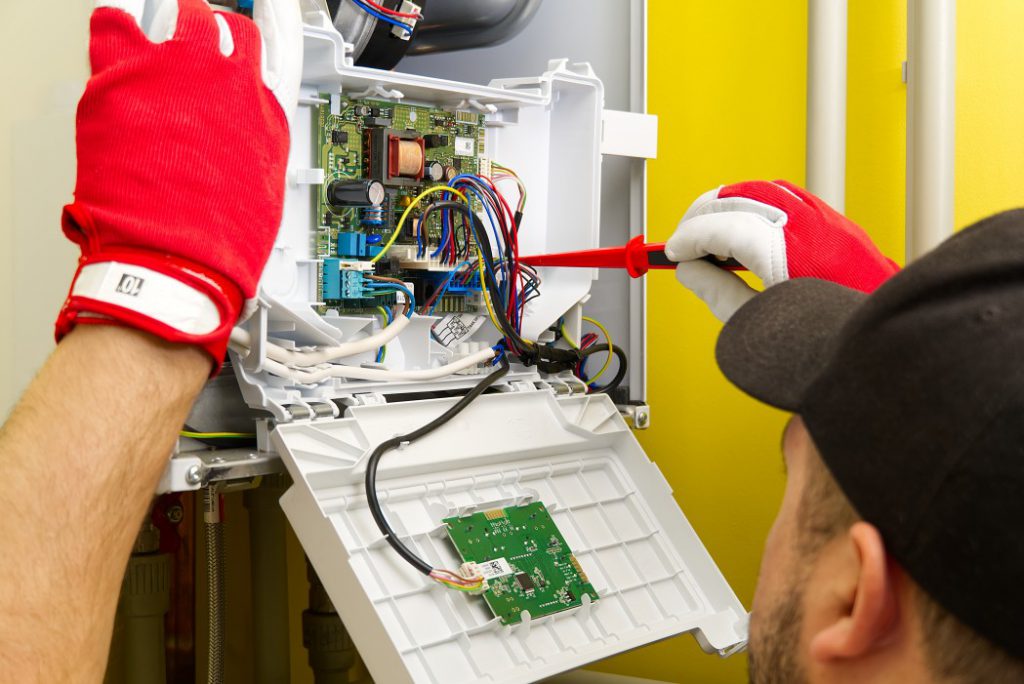

Commercial electrical maintenance involves the routine inspection, testing, and repair of electrical systems and components within commercial buildings. This practice ensures that electrical installations operate efficiently and safely, minimizing risks of failure and enhancing overall performance. An effective maintenance program addresses various aspects including wiring, circuit breakers, outlets, and lighting systems. By adhering to systematic maintenance protocols, businesses can extend the lifespan of their electrical systems, ensuring compliance with local codes and safeguarding personnel.

Importance of Regular Maintenance

Regular maintenance of electrical systems is critical for several reasons. Firstly, it enhances safety by reducing the risk of electrical fires and accidents, which can result in injury or property damage. Secondly, proactive maintenance can lead to significant cost savings. By identifying issues early, businesses can avoid costly repairs or replacements due to electrical failure. Additionally, routine inspections help maintain compliance with safety regulations, protecting organizations from legal repercussions and penalties. Thus, implementing a well-structured commercial electrical maintenance plan is essential for all businesses.

Key Components to Inspect

Key components in a commercial electrical system that should undergo regular inspections include:

- Wiring: Inspecting for signs of wear, corrosion, or loose connections contributes to overall safety.

- Circuit Panels: Ensuring that circuit breakers are functioning correctly helps prevent overloads and short circuits.

- Grounding Systems: Proper grounding is crucial for safety to reduce the risk of electric shock.

- Lighting Fixtures: Dimming or flickering lights can indicate underlying electrical issues that need addressing.

- Emergency Systems: Regular checks on emergency lighting and exit signs ensure that safety protocols are effectively in place.

Common Challenges in Electrical Maintenance

Identifying Potential System Failures

Identifying potential system failures can be challenging due to the complexity of electrical systems. Often, problems manifest subtly, with symptoms that may go unnoticed until they result in significant damage. Regular inspections are crucial, but additional monitoring technologies, such as infrared thermography, can help detect hot spots in electrical panels and wiring long before they lead to failures. Thus, proactive identification of risks is essential for preventing unforeseen accidents and ensuring operational continuity.

Compliance with Safety Regulations

Compliance with safety regulations presents another challenge in commercial electrical maintenance. The legal landscape governing electrical work can vary widely by location and often changes. Companies must remain diligent about staying updated on local, state, and national codes. This necessitates not only a strong understanding of the regulations but also a commitment to ongoing education and training for maintenance personnel. Regular reviews of compliance practices and documenting all maintenance activities can help organizations mitigate legal risks.

Managing Costs Effectively

Effective cost management in electrical maintenance involves balancing the need for thorough inspections and repairs with available budgets. Many businesses may view maintenance as an expense rather than an investment. However, failing to allocate sufficient resources can lead to expensive emergencies and downtime. Implementing a predictive maintenance plan that utilizes advanced monitoring technologies can optimize maintenance costs. By predicting failures rather than reacting to them, businesses can save substantially while ensuring safe operational efficiency.

Best Practices for Commercial Electrical Maintenance

Creating a Maintenance Schedule

Creating a comprehensive maintenance schedule is pivotal for efficient management of commercial electrical systems. This schedule should outline routine inspections, testing protocols, and record-keeping practices. A well-constructed schedule provides clarity on when each system component is due for inspection or servicing, ensuring nothing is overlooked. Additionally, a calendar-based reminder system can help maintenance teams stay on top of their tasks, facilitating timely interventions and reducing the risk of system failures.

Training Staff on Electrical Safety

Training staff on electrical safety is critical for any commercial establishment. Employees should receive comprehensive training on electrical hazards and safe working practices. This training can cover topics like proper use of electrical equipment, understanding circuit layouts, and emergency response protocols. Furthermore, having clear safety guidelines and regular safety drills can significantly enhance the overall safety culture within the organization, minimizing risks related to electrical mishaps.

Utilizing Technology for Monitoring

Incorporating technology into electrical maintenance practices offers substantial benefits. Advanced monitoring systems can provide real-time data on energy usage, system performance, and potential issues. Implementing IoT devices to monitor equipment health can lead to proactive maintenance, preventing unexpected outages. Status alerts can notify maintenance teams of abnormal conditions, allowing for immediate intervention. This tech-driven approach not only enhances operational efficiency but also minimizes costs associated with unplanned downtime.

Implementing a Successful Maintenance Program

Steps for Developing a Program

To implement a successful electrical maintenance program, organizations should follow several strategic steps. Initially, conducting a thorough assessment of existing electrical systems lays the foundation for the program. This includes identifying critical systems, potential vulnerabilities, and associated risks. Subsequently, businesses should develop tailored maintenance protocols based on the assessment findings. Assigning responsibilities and scheduling regular reviews will ensure sustained program effectiveness. Moreover, involving cross-departmental teams ensures that maintenance practices align with overall operational goals.

Key Performance Indicators to Track

Tracking key performance indicators (KPIs) is essential for evaluating the success of maintenance programs. Important KPIs to monitor include:

- Downtime: Monitoring the frequency and duration of unplanned outages helps assess system reliability.

- Maintenance Costs: Evaluating overall expenses related to maintenance versus repairs can inform budgeting decisions.

- Inspection Completion Rates: Ensuring all scheduled inspections and repairs are completed on time reflects program adherence.

- Energy Efficiency: Tracking energy usage helps identify unusual spikes or drops, signaling potential electrical issues.

Evaluating the Effectiveness of Maintenance

Regular evaluation of the electrical maintenance program is necessary to ensure its effectiveness. This process should include reviewing the success of preventive measures, analyzing maintenance data, and gathering feedback from maintenance personnel and staff. Periodic audits can also reveal potential areas for improvement, allowing organizations to refine protocols and enhance their strategy over time. Making adjustments based on this feedback ensures that the maintenance program remains relevant and effective in addressing evolving challenges.

Frequently Asked Questions About Commercial Electrical Maintenance

What is the average cost of commercial electrical maintenance?

The average cost can vary widely based on the size of the business, the complexity of electrical systems, and the maintenance frequency. Typically, organizations can expect to allocate a portion of their budget for regular inspections and repairs, but investing in preventive maintenance often yields significant savings over time.

How often should electrical systems be inspected?

It is generally recommended that commercial electrical systems undergo inspections at least once a year. However, high-usage facilities may benefit from biannual or quarterly inspections to ensure optimal performance and safety.

What are the signs of electrical issues in commercial buildings?

Signs of electrical issues include flickering lights, frequent circuit breaker tripping, burning smells, unusual sounds from outlets or switches, and warmer than usual wiring. These symptoms often indicate underlying problems that need immediate attention.

Can regular maintenance prevent electrical hazards?

Yes, regular maintenance can significantly reduce the risk of electrical hazards. Routine inspections can help identify potential failures and ensure that systems operate safely and efficiently, minimizing risks of electrical fires and accidents.

What qualifications should electricians have for commercial maintenance?

Electricians responsible for commercial maintenance should possess appropriate licensing and certifications, experience in commercial settings, and a strong understanding of local electrical codes and safety regulations. Continuous education and training in current technology and practices are also essential.